I thought that I might share with you all some thematic consistencies that I have noticed across my courses this year. While these motifs may be broad in their scope, and as such can be applied to any engineering specialization, I will try and put an EEE twist to them all.

Simulations and their pitfalls

Simulations can, and will, lie to you. They are only as good as the data and set up that is provided to them, which is provided by oneself, who is often wrong and is subject to the most painful of foibles: human error and hubris. The pity is that it can be so easy to forget this, as one ends up taking the computers word as gospel, when in fact it is just a regurgitation of one’s own incompetence.

Don’t get me wrong, simulations are arguably the most useful tool available to you, but you must always be cautious when using them. They should be used to validate your answers and provide reassurance as to the working you had done; use simulations as an audit to your work and learn to find solace when they agree with you.

Really what I am trying to say is do not use LTSpice or falstad to solve problems for you, learn how to solve the problems first, and only then should you look for congruous simulation results.

Practical components

I have already touched on the world of practical components in my previous blog, but it is worth going into a bit more detail. Selecting components comes down to compromise as you attempt to find the best possible solution to an open-ended problem. Just about every component comes with an asterisk, also known as the datasheet.

The idiosyncrasies of practical components can be grouped into three main categories: values, limits, and imperfections.

- Values: there are only a fixed set of readily available component (resistors and capacitors mainly) values which are encapsulated in the E series of preferred numbers. For example, you cannot easily get a 5-ohm resistor, but you could instead get a 4.7-ohm or 5.6-ohm resistor since the latter two values are from the readily available E12 series.

- Limits: all devices have operating limits, be they voltage, power or otherwise. Letting a device operate outside of its limits can lead to undesirable behavior.

- Imperfections: the more obvious imperfection is tolerance – the actual value of a component will deviate from what it says on the packet. For example, the E12 series has a 10% tolerance so that 18k-ohm resistor you just picked up could range anywhere between 16.2k-ohm and 19.8k-ohm. However, the tolerances are normally distributed, so you are probably going to get a value that is close to what you had expected – nevertheless, something to bear in mind. The other imperfections come from the physical construction of components – literally everything has an internal impedance: resistors have some internal inductance; capacitors have extra internal inductance and resistance. As such you end up with a range of different types of one component. Capacitors are a great example, with ceramic and electrolytic varieties each having markedly different characteristics while still being capacitors: electrolytic capacitors are available in higher capacitances while suffering from high internal impedances, while ceramic capacitors have much lower internal impedances to go a long with a significantly smaller capacitance.

The transition from theory to practicum

As this year has progressed, we have been learning more and more about how we can better predict, and create for, the real world. On the analytical side this results in more detailed component models to better represent the real-world behavior of components (those of you who did NCEA Level 3 Physics may remember modelling the internal resistance of batteries). More accurate modelling becomes incredibly useful when we begin to look at non-linear devices (you learn about linearity in ELECTENG 291, it is what allows you to use superposition, Thévenin’s theorem etc. – VERY useful) as we can approximate them in linear ways which drastically simplifies the analysis.

In terms of creating for the real world, ELECTENG 209 teaches techniques and tips required to transform a schematic to a physical product. You learn all about the design of the increasingly important PCB, from how to lay out traces to the nuances of component selection.

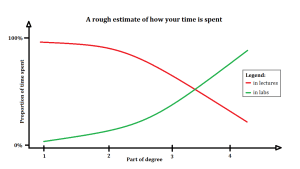

This transition to practicum has led to a trend that I have noticed. Excuse the crude visualization, but I feel that it does get the point across nicely.

Becoming a real engineer

Who am I to call anyone a ‘real’ engineer? Great question.

As you complete more of the frighteningly exciting design projects that better represent your professional future, the skills that this hypothetical future professional requires must be learnt by someone, and that someone is you. Some are more interesting than others, but I am afraid that they must all be learnt. How about we try a bulleted list for some brevity (this is by no means an exhaustive collection).

- Read emails and announcements. They often contain useful and/or important information that can be particularly pertinent.

- Take note of your work. Design projects will require you to keep a logbook: the combination of the documentation that you produce over the course of the project should allow someone new to follow your entire process without needing to talk to you. Every meeting, each calculation, decisions big and small – take note of them!

- Communication: I don’t think that it is anyone’s favourite, but then again you do have an entire one-thousand-dollar course dedicated to practicing it; make use of that time. Meetings are a non-negotiable part of the professional life, so take the time to prepare for them. Across all the courses that you take the importance of communication lingers. Lab partners, lecturers and group members all work best when communicated with.

- Failing to plan is planning to fail. Eww, how cliché of you Fraser; can you not write something original for once in your life. Sorry … but it is a useful adage. Schedule your time to the best of your ability – engineers tend to be a little too optimistic so at least double, or even triple, your initial time estimates for tasks to account for the inevitable setbacks. Tools like Trello, Gantt charts, or even plain old Excel can all reduce the headache that is task distribution and allotment for group projects.

That is enough for now. Come back soon (well, only if you are hanging on my every word) for a blog about … something; I haven’t decided yet. Oh well.

Have I actually done a good job of attracting budding Electrical & Electronics Engineers, or has this whole editorial been counterproductive?

Apologies to Simple Minds for the egregious rip-off that is the cover image.

– Fraser

Great article, here I would like to thank you guys for sharing such a fantastic blog. Regards Genus Electrotech Ltd. – PCb Board Manufacturer in India